Industrial Cylinder Brushes|Custom Sizes&Materials

High durability & precise machining for diverse industrial needs

- Home /

- Category-Cylinder Brush

Nylon

Metal Wire

Sisal

Animal Hair

PP (Polypropylene)

Abrasive Wire

Advanced Manufacturing Processes

Drilled Bristle Insertion

Drilled Bristle Insertion is the process of drilling holes in a plastic, wooden, or metal base according to any density and arrangement design. After that, bristles (which may include nylon PP animal hair among others) are placed inside the said holes by use of a bristle setting machine and fixed by use of metal nails wires or through fusion splicing.

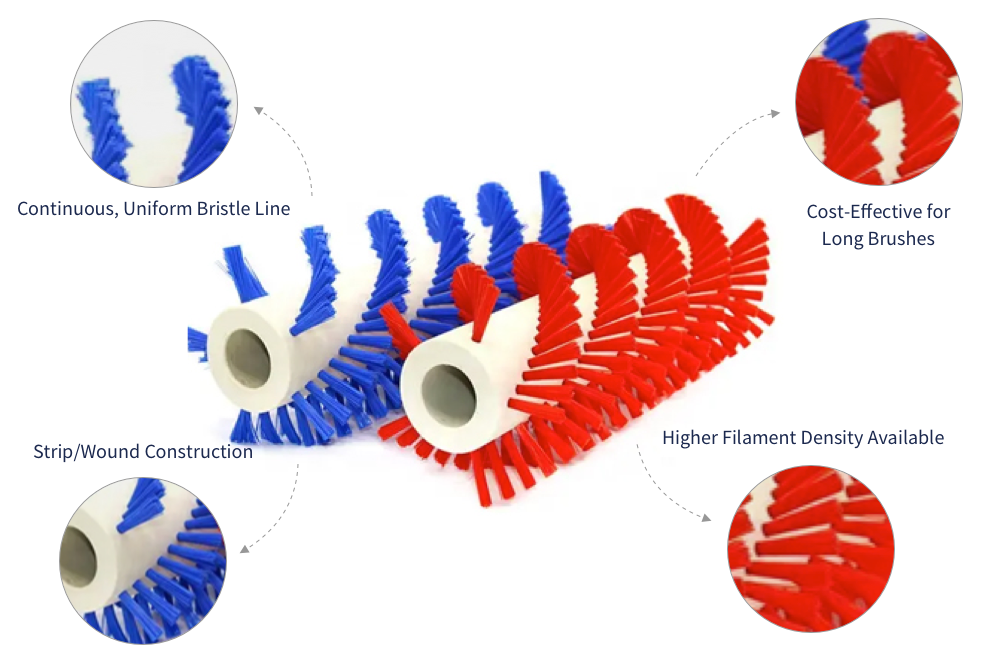

Strip/Wound Construction

It is the type in which bristles (commonly filaments or metallic wires) are attached to a core (that may be an iron core, steel wire, or metal strip), by forming the body of the brush into a spiral setup through continuous winding, pressing, or welding.

Advanced Manufacturing Processes

Uniform Contact

The density and setting of the Cylinder brush ensure that force is applied equally all over the surface of the brush, which can help in maintaining consistency in workpiece surface treatment.

High Wear Resistance

Made from chosen materials and by a high-standard process, in cleaning and grinding performance product stays good even after long-time operation.

Customization Flexibility

Customization based on its diameter, length, filament diameter, and hardness is available to suit different equipment.

Multi-Condition Adaptability

The Cylinder brush is compatible with dry and wet environments, different speeds, and various material surfaces, offering wide and stable application.

Custom Cylinder Brush Configurations

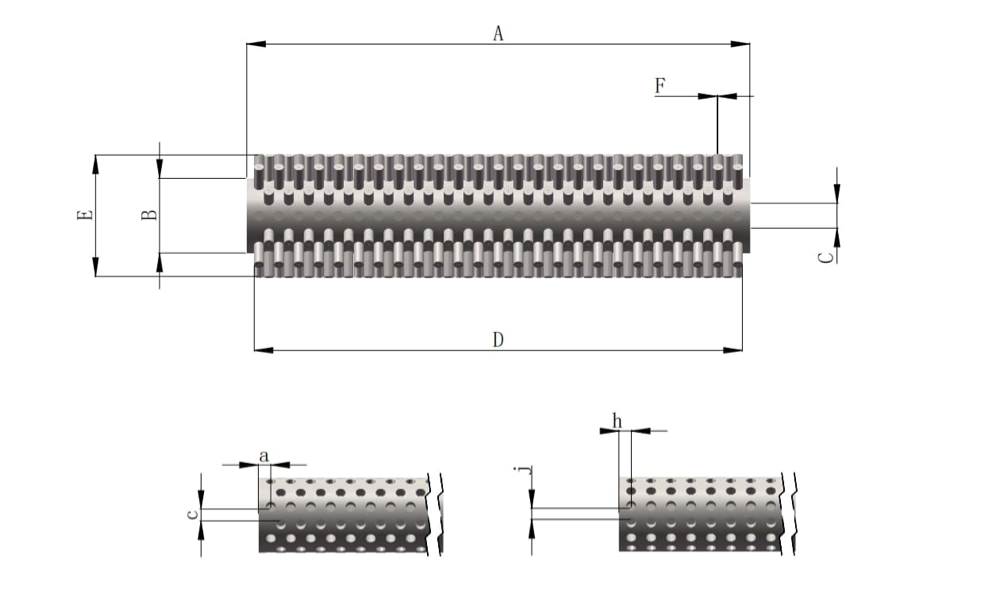

Tufted Cylinder Brush

Tufted Cylinder Brush

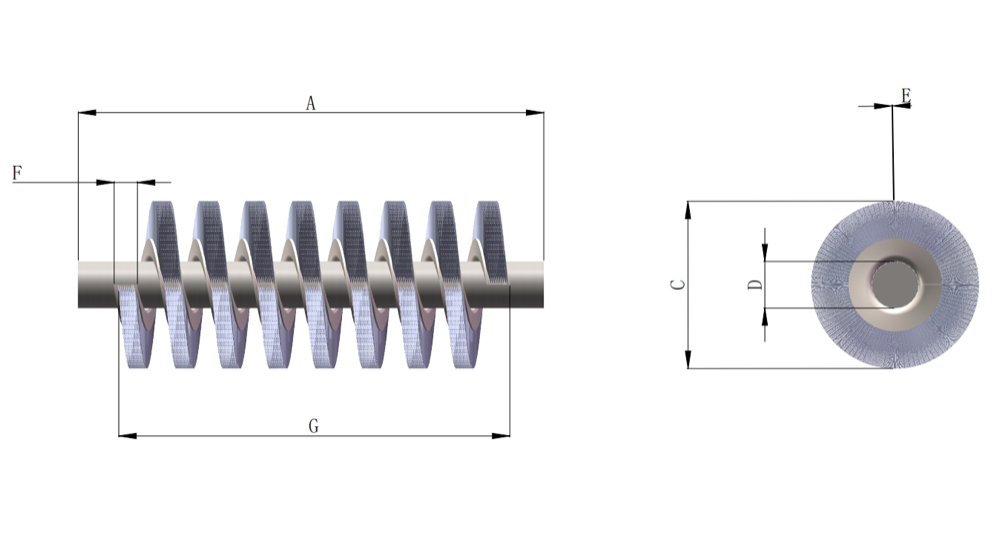

Wound Cylinder Brush

Wound Cylinder Brush

We'd like to work with you

At Fortex Brushes, we believe trust is built through action, not words — through every product we deliver and every partnership we honor.

We don’t just manufacture brushes; we create smart, efficient, and sustainable brushing solutions that help our partners operate cleaner, safer, and more effectively.

- +86-19850701602

- +8619850701602

- hershey@gwbrush.com

Contact Us

What specifications are needed to customize a cylinder brush?

To design a cylinder brush that perfectly fits your equipment, you’ll need to provide the rotating shaft diameter, total brush length, filament type, and working environment (dry/wet, speed, material type). Our engineers will recommend optimal parameters accordingly.

How to choose the right filament material for different applications?

Each filament type has unique performance advantages. For example, nylon for fine surface polishing, metal wire for rust removal, PP for chemical-resistant environments, and abrasive filament for tough grinding. Choosing the right one ensures efficiency and durability.

What’s the difference between Drilled Bristle Insertion and Wound Construction?

The Drilled Bristle Insertion method ensures high structural stability and precise arrangement, ideal for dense and replaceable tufts. The Wound Construction technique offers continuous filament lines and cost efficiency for long brushes.

How long does a cylinder brush typically last?

Lifespan depends on material, contact pressure, and environment. Thanks to top-tier filament and precision mounting, our brushes maintain performance even after thousands of operating hours. Regular maintenance further extends service life.

Do you provide testing samples before mass production?

Absolutely. We offer low-cost sample testing with no MOQ, so you can verify results before bulk purchasing and proceed with full confidence.