Industrial Brush for Solar Panel Cleaning

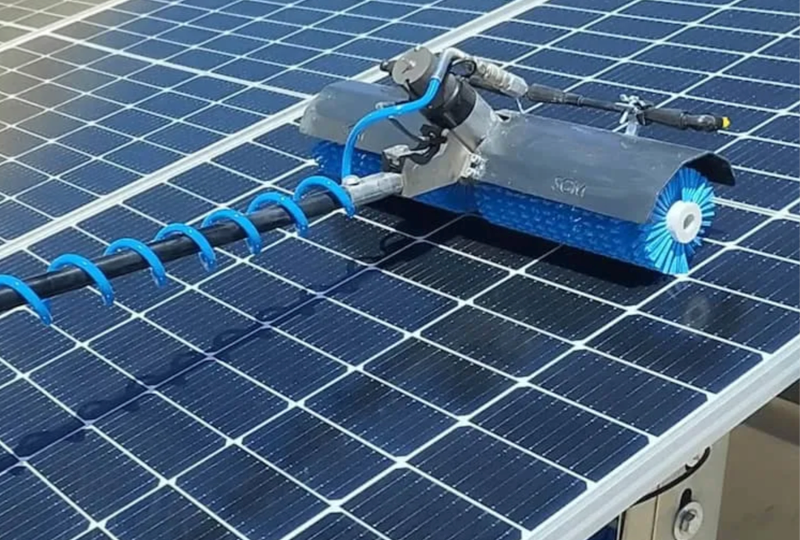

Made of materials that will last with heads that are quick to change, these brushes provide deep yet gentle cleaning from rooftop arrays to large solar farms. They stay productive over a long life, keeping maximum solar output with minimum maintenance.

- Home /

- Application-Solar Panel Cleaning Brush

Industry Pain Points & Our Proven Solutions

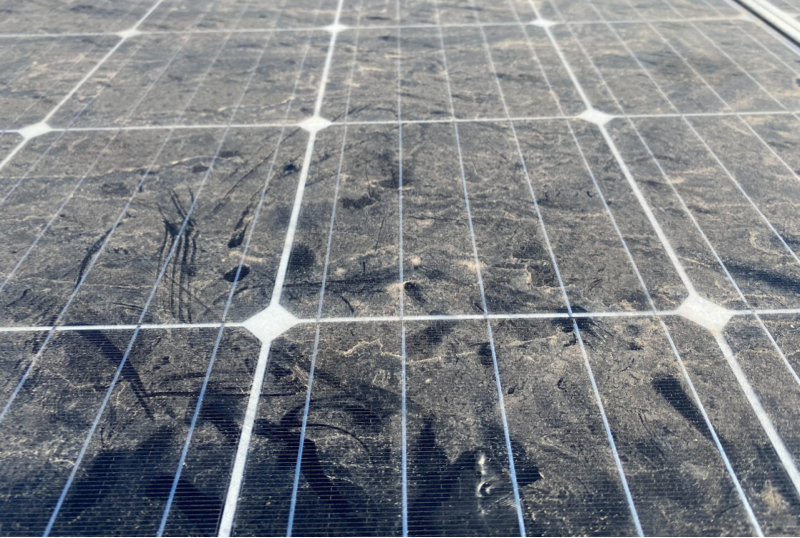

Still Struggling with Dust, Bird Droppings and Stains on Solar Panels?

Problem:

Airborne dust, bird droppings, and mineral stains adhere tightly to panel surfaces, blocking sunlight and reducing energy output by up to 30%. Manual wiping often leaves residues or streaks.

Our Solution:

- Ultra-soft fine nylon filaments (0.2–0.3mm) that penetrate surface texture without scratching glass.

- Integrated water feed system flushes away loosened contaminants, leaving a spotless finish and restoring peak efficiency.

Still Worried About Scratches During Cleaning?

Problem:

A hard brush or contaminated tool will easily scratch the solar glasses, destroy coatings, and void warranties from manufacturers.

Our Solution:

- The material of the brush shall not be abrasive. Rounded filament tips shall be certified safe for use on tempered solar glass.

- Safety edge guard design does not allow contact with frame, always ensuring safe and uniform cleaning.

Protective edge guard design prevents frame contact, ensuring safe and uniform cleaning every time.

Still Facing Frequent Downtime Due to Brush Wear and Replacement?

Problem:

Common brushes tend to wear off easily under outdoor conditions (exposure to UV, and dust particles), thus causing frequent replacement, resulting in costly maintenance stoppages.

Our Solution:

- Composite filaments that are UV- resistant and wear- proof last 3× longer than standard brushes.

- Quick-change mechanism – replace brush heads in under 5 minutes, reducing downtime and labor cost.

Related Products

Cylinder Rotary Brush

Outside Coil Brush

Nylon Cylinder Brush3

Nylon Cylinder Brush3

Expert Guides for Better Brush Applications

Unlock the full potential of your cleaning system with our professional insights.

From step-by-step installation to smart selection tips, explore how to choose, use, and maintain brushes that perfectly fit your unique application.

A Complete Guide to Choosing Your Furniture Polishing Brush

ind the ideal furnit

Understanding Heat-Resistant Glass: Safety, Standards, and Smart Consumer Choices

Glass has long been

What We Can Support You

Fortex Brushes — Your Partner for Continuous Success!

Recommend the Best Product Solution

We help you select the most suitable brush based on your specific application, ensuring optimal performance in every polishing process.

Design the Perfect Parameters

All brush materials and sizes are customized precisely according to your equipment and working conditions — for a perfect match and superior results.

Provide Low-Cost Sample Testing (No MOQ)

You can test samples before mass production to verify actual performance and make confident purchasing decisions.

Continuous Improvement Support

We stay connected after delivery — you can share usage feedback anytime, and we’ll help you refine brush design for better durability and efficiency.

Can the brush clean without scratching the solar panel surface?

Yes, the brush uses soft, non‑abrasive bristles that gently remove dust and stains while keeping the glass coating safe.

Is the brush suitable for large solar farms or only for home use?

It works perfectly for both. The brush can be attached to telescopic poles or cleaning machines, making it efficient for large installations as well as small rooftop panels.

How long does the brush last under outdoor conditions?

With UV‑resistant and rust‑proof materials, the brush is designed for long‑term outdoor use. Even under strong sun or rain, it maintains its shape and cleaning performance for extended periods.